State-of-the-Art Equipment & Industry-leading Engineering and Operations

With state-of-the-art equipment and an industry-leading engineering and operations team, MAC is ready to help solve any composite material challenge. MAC has a dedicated facility to develop and manufacture composite prepregs and can support secondary operations such as cutting and plying and flat laminate production.

In addition to prepreg production, Montana Advanced Composites can support material characterization and acceptance/qualification testing.

With state-of-the-art equipment and an industry-leading engineering and operations team, MAC is ready to help solve any composite material challenge. MAC has a dedicated facility to develop and manufacture composite prepregs and can support secondary operations such as cutting and plying and flat laminate production.

In addition to prepreg production, Montana Advanced Composites can support material characterization and acceptance/qualification testing.

Manufacturing Capabilities

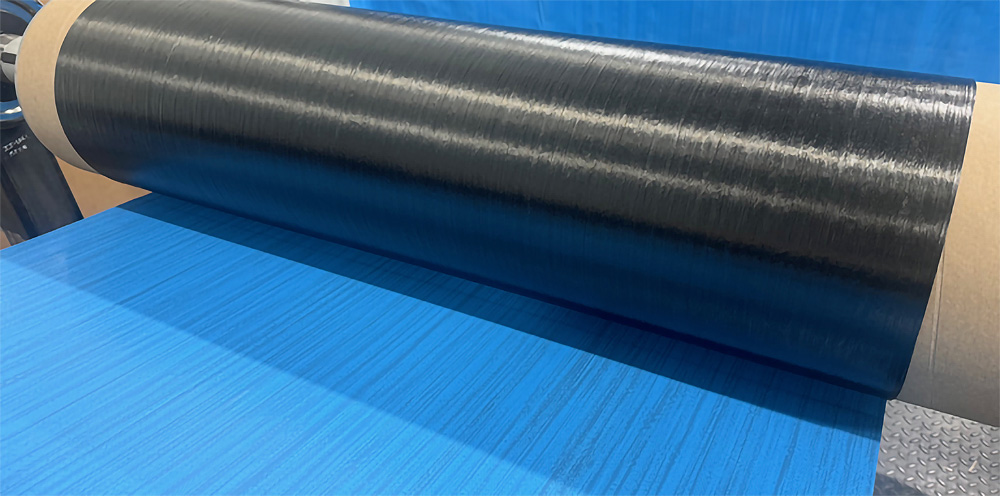

Prepreg Production

- Direct impregnation, 50” wide, hot-melt coating line

- Film line, 50” wide, multi-roll coating line

- Prepreg line, 50” wide, tape and fabric

Secondary Operation Capabilities

- Cut and ply at various orientations

- Multi-opening press for flat laminate production

- Slitting and rewinding

Testing Capabilities

Analytical Lab – Physical and Thermal Testing

- RC/FAW, Fiber Volume/Void Content

- Rheological Analysis

- Thermogravimetric Analysis (TGA)

- Differential Scanning Calorimetry (DSC)

- Dynamic Mechanical Analysis (DMA)

- Thermal Mechanical Analysis (TMA)

- Fourier Transform Infrared Spectroscopy (FTIR)

- Dielectric Withstanding Voltage (DWV)

Mechanical Testing And Other

- Multiple Servo-electric Load Frames:

- Tension

- Compression

- Short Beam Shear

- In Plane Shear

- Flexural

- Impact

- Flammability

- Fatigue

- RF Testing, Dk/Df